In today's increasingly competitive packaging and printing industry, equipment maintenance quality directly affects production efficiency and product quality. Traditional equipment maintenance relies mainly on the accumulation of experience by technicians and paper-based operating procedures. This method has pain points such as inconsistent standard execution, inaccurate grasp of details, and slow training of new personnel. The introduction of 3D animation technology is bringing innovative solutions to the standardization of packaging and printing equipment maintenance.

Establishment and Implementation of Visualized Operating Procedures

The primary task of equipment maintenance standardization is to establish clear and definite operating procedures. Through precise equipment modeling and dynamic demonstrations, 3D animation transforms abstract maintenance requirements into intuitive visual guidance. Compared with traditional 2D drawings and text descriptions, 3D animation can display maintenance details from multiple angles, ensuring that every technician can accurately understand and execute unified standards.

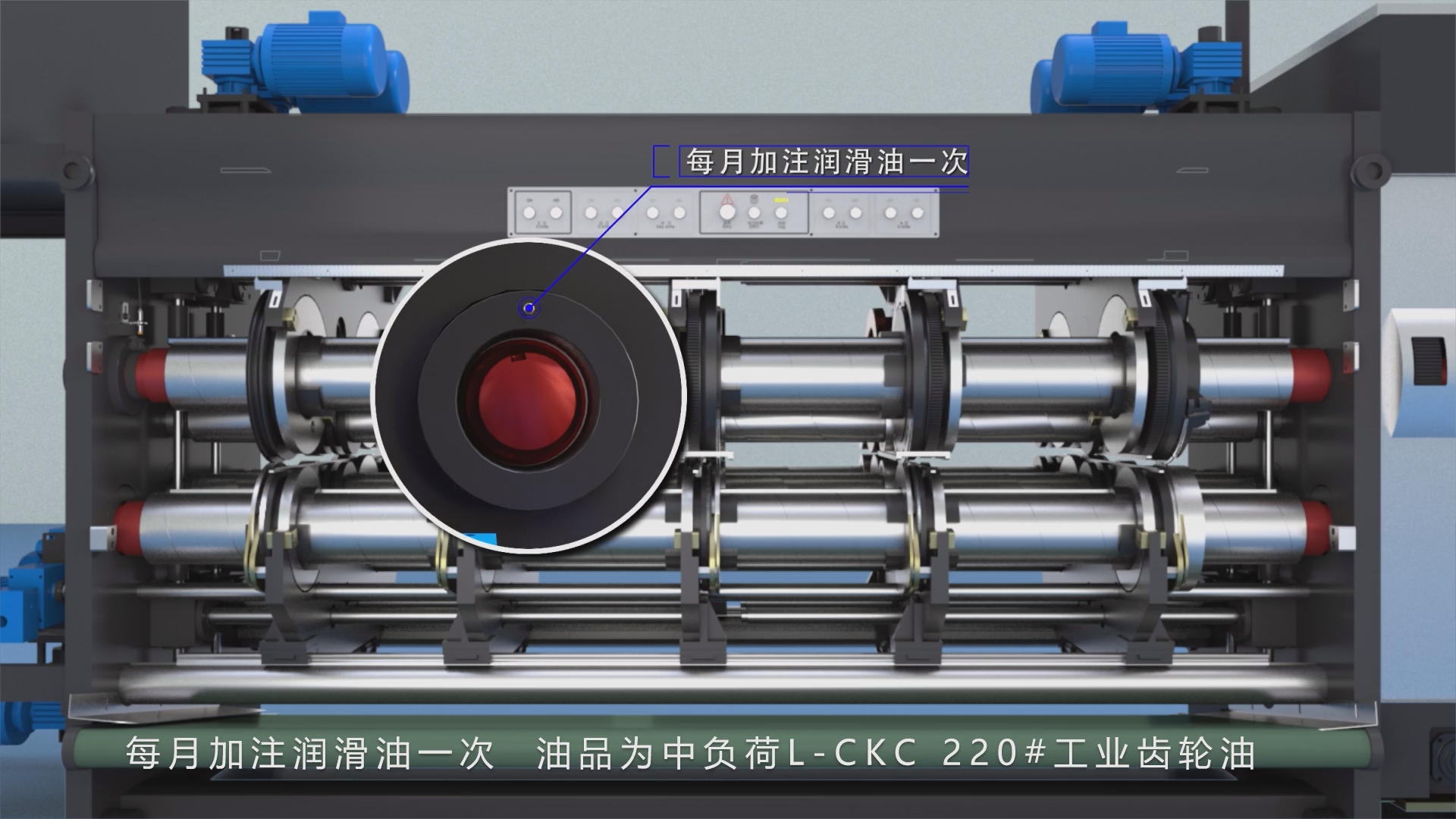

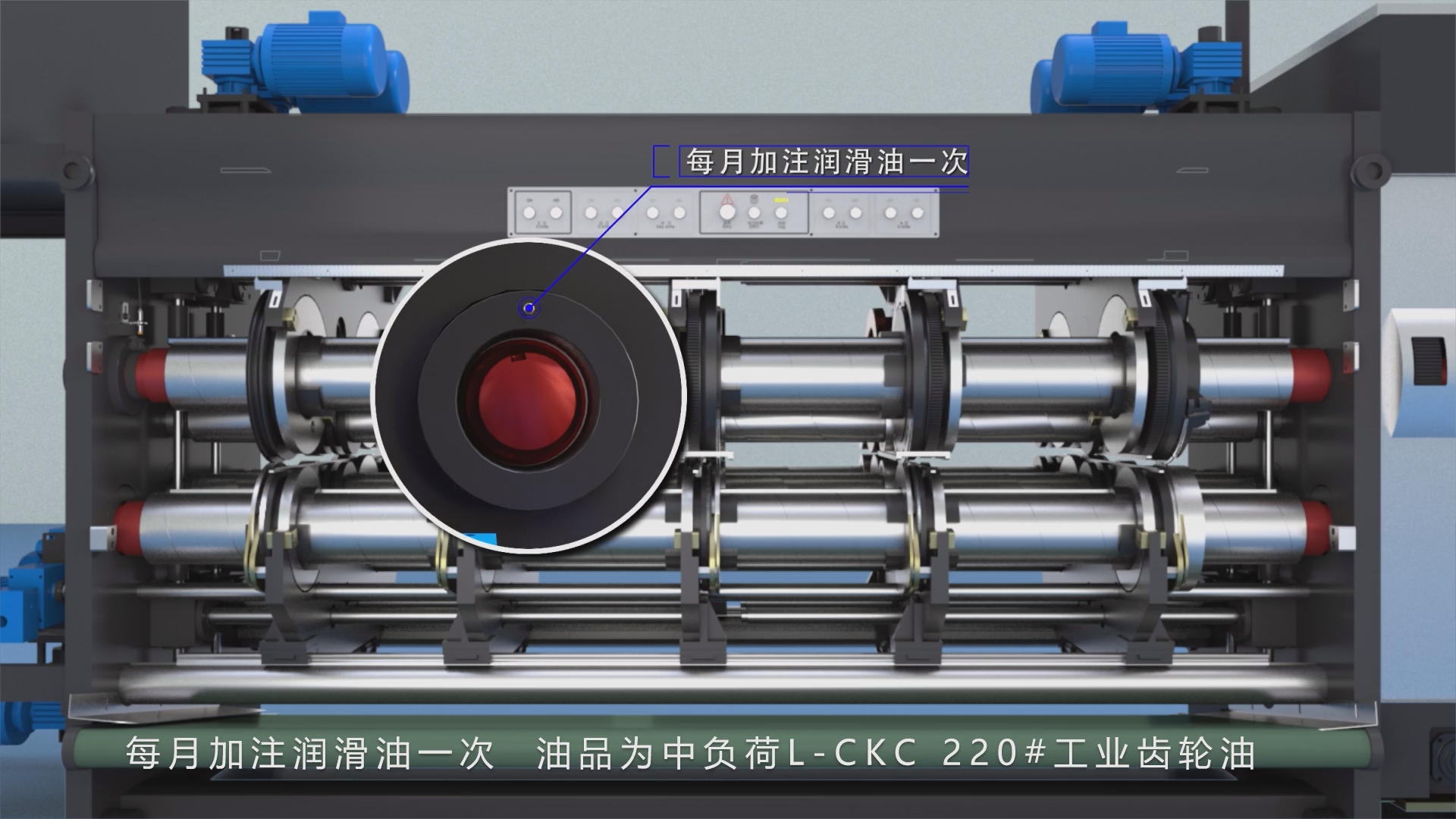

In the practice of Guangdong Tuopin Intelligent Machinery Technology Co., Ltd., the maintenance animation for the water-based ink printing machine detailed the entire process from daily cleaning to regular maintenance. The animation not only clarified the operating steps for each maintenance link but also highlighted the key maintenance points of critical components through close-up shots and slow-motion demonstrations. This visual guidance enables technicians of different skill levels to perform maintenance operations according to unified standards, significantly improving the consistency of maintenance quality.

Construction of a Preventive Maintenance System

The stable operation of packaging and printing equipment is inseparable from a scientific preventive maintenance system. By demonstrating equipment operating mechanisms and wear patterns, 3D animation helps technicians develop awareness and methods for preventive maintenance. Animations can clearly present the service life cycle of key equipment components, warn of potential failure risks, and guide technicians in performing timely preventive maintenance.

In practical applications, this preventive maintenance system shows significant value. Guided by 3D animation, technicians can accurately grasp the timing for maintenance of various components, avoiding resource waste caused by over-maintenance and preventing equipment failures due to insufficient maintenance. Practice data from Tuopin Company shows that after implementing the 3D animation-based preventive maintenance system, the rate of unexpected equipment failures decreased by 35%, and the overall equipment efficiency increased by 28%.

Precise Management of Maintenance Processes

3D animation technology provides an effective tool for achieving precise management of the maintenance process. By integrating elements such as maintenance standards, operating procedures, and quality requirements into the animation system, companies can establish a comprehensive maintenance management database. This system not only guides on-site operations but also enables the traceability, evaluation, and optimization of the maintenance process.

In specific implementation, technicians learn maintenance standards and execute maintenance tasks through the animation system, recording the maintenance status. Managers can monitor maintenance progress and quality in real-time through the system, identifying and resolving issues promptly. This precise management approach enhances supervision of the maintenance process and provides a basis for continuous improvement. More importantly, the accumulated maintenance data provides empirical support for optimizing maintenance cycles and standards.

Systematic Inheritance of Maintenance Knowledge

Continuous improvement of packaging and printing equipment maintenance levels requires the establishment of an effective knowledge inheritance mechanism. 3D animation systematically accumulates and inherits maintenance knowledge by transforming personal experience and best practices into standardized visual content. This knowledge management method preserves the valuable experience of senior technicians while providing an effective pathway for the learning and growth of new employees.

The case of Xiamen Sanlei Packaging Materials Co., Ltd. fully demonstrates this value. The company has established a comprehensive maintenance knowledge base through 3D animation. New employees can quickly grasp key equipment maintenance points via the animation system, significantly shortening the training period. Furthermore, the experiences and lessons from each maintenance case can be consolidated into animation form, continuously enriching the company's knowledge assets. This systematic knowledge inheritance ensures the continuous improvement of the company's maintenance standards.

Visualized Evaluation of Maintenance Quality

Traditional maintenance quality evaluations often rely on the subjective judgment of evaluators, leading to inconsistencies in standards. 3D animation provides objective visual standards for maintenance quality assessment. By transforming standard maintenance procedures in animations into specific evaluation metrics, a quantitative assessment system is established, making the evaluation of maintenance quality more scientific and accurate.

In practice, evaluators can refer to the standards demonstrated in 3D animations to objectively assess each stage of maintenance operations. Dimensions such as the standardization of maintenance procedures, accuracy of operational details, and completeness of task completion can be quantitatively evaluated. This visual evaluation method not only improves assessment accuracy but also provides clear direction for technicians to improve their maintenance work.

Optimized Allocation of Maintenance Resources

3D animation technology also plays an important role in optimizing the allocation of maintenance resources. By analyzing equipment operating data and maintenance records, combined with the equipment structure and maintenance requirements displayed in 3D animations, companies can plan maintenance resources more scientifically and maximize resource utilization efficiency.

Specifically, companies can arrange maintenance plans based on equipment maintenance demand forecasts provided by the animation system, optimizing personnel allocation and spare parts inventory. This optimized resource allocation ensures timely maintenance of critical equipment while avoiding idle waste of resources. Practice shows that after optimizing resource allocation through the 3D animation system, maintenance costs were reduced by 20%, while equipment reliability significantly improved.

Establishment of a Continuous Improvement Mechanism

3D animation technology also provides a platform for the continuous improvement of maintenance standardization work. By recording and analyzing data and cases from the maintenance process, companies can continuously identify shortcomings in maintenance standards and promptly optimize and improve them. This continuous improvement mechanism ensures the ongoing enhancement of the company's maintenance standardization level.

During implementation, companies can promptly translate best practices summarized from maintenance operations into 3D animation content, updating and refining maintenance standards. Simultaneously, technicians can provide feedback on issues and suggestions encountered in practice through the animation system, forming a virtuous interactive improvement cycle. This continuous improvement mechanism ensures that the company's equipment maintenance work always maintains an advanced level.

Through multiple dimensions such as visualized procedure establishment, preventive system construction, and precise process management, 3D animation technology offers innovative solutions for the standardization of packaging and printing equipment maintenance. This technological application not only enhances the efficiency and quality of maintenance work but, more importantly, establishes a standardized system for continuous improvement. With the continuous development of technology and deeper application, 3D animation will undoubtedly play an even more significant role in the field of packaging and printing equipment maintenance.

Featured FAQs:

Q: Will maintenance operation animations expose sensitive equipment structures?

A: No.

Maintenance operation animations demonstrate the content of traditional paper operation manuals in the form of animated videos (e.g., the feeding unit in a printing press mainly explains how to adjust baffles and guides, and how to load paper; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, none of which involve sensitive equipment structures). Machine manufacturers can also delete or deform sensitive equipment structures when providing equipment models.

The initiative always remains with the machine manufacturer.

Q: Are maintenance operation animations very expensive?

A: Conclusion first: Equipment maintenance operation animations create value for machine manufacturers. The greater the investment, the greater the return.

The production cost for equipment maintenance operation animations generally ranges from tens of thousands to over a hundred thousand yuan, or even higher. While seemingly expensive, the average cost per machine is not high.

How do equipment maintenance operation animations create value for machine manufacturers?

1. Low amortized cost. Machine equipment generally undergoes minor modifications every 2 years and major ones every 4 years. The total cost of animation production is very low when amortized across each machine;

2. Equipment premium. According to actual measured data from machine manufacturers, for every yuan invested in producing maintenance operation animations, the resulting equipment sales premium is about 3-5 yuan (i.e., 3-5 times);

3. Significantly reduces after-sales service costs, especially during the equipment warranty period;

4. Effectively increases customer loyalty;

5. More competitive compared to similar products.

Characteristics: Significant initial investment, very small subsequent investment.

Q: Which equipment is suitable for producing maintenance operation animations?

A: Almost all equipment is suitable for producing maintenance operation animations, from single machines costing millions to those costing tens of thousands or even a few thousand yuan.

Producing equipment maintenance operation animations addresses after-sales service issues on one hand, and on the other hand, enhances the brand and product premium, better promotes sales, and increases customer loyalty.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients span various types of enterprises including startup teams, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation for mechanical equipment, high-tech industries, software development, foreign trade companies, etc., offering one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

We have provided nearly 3000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at exhibition sites or during client visits; whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in stunning 3D animation. This not only brings a unique visual experience to clients but also quickly resonates with them.